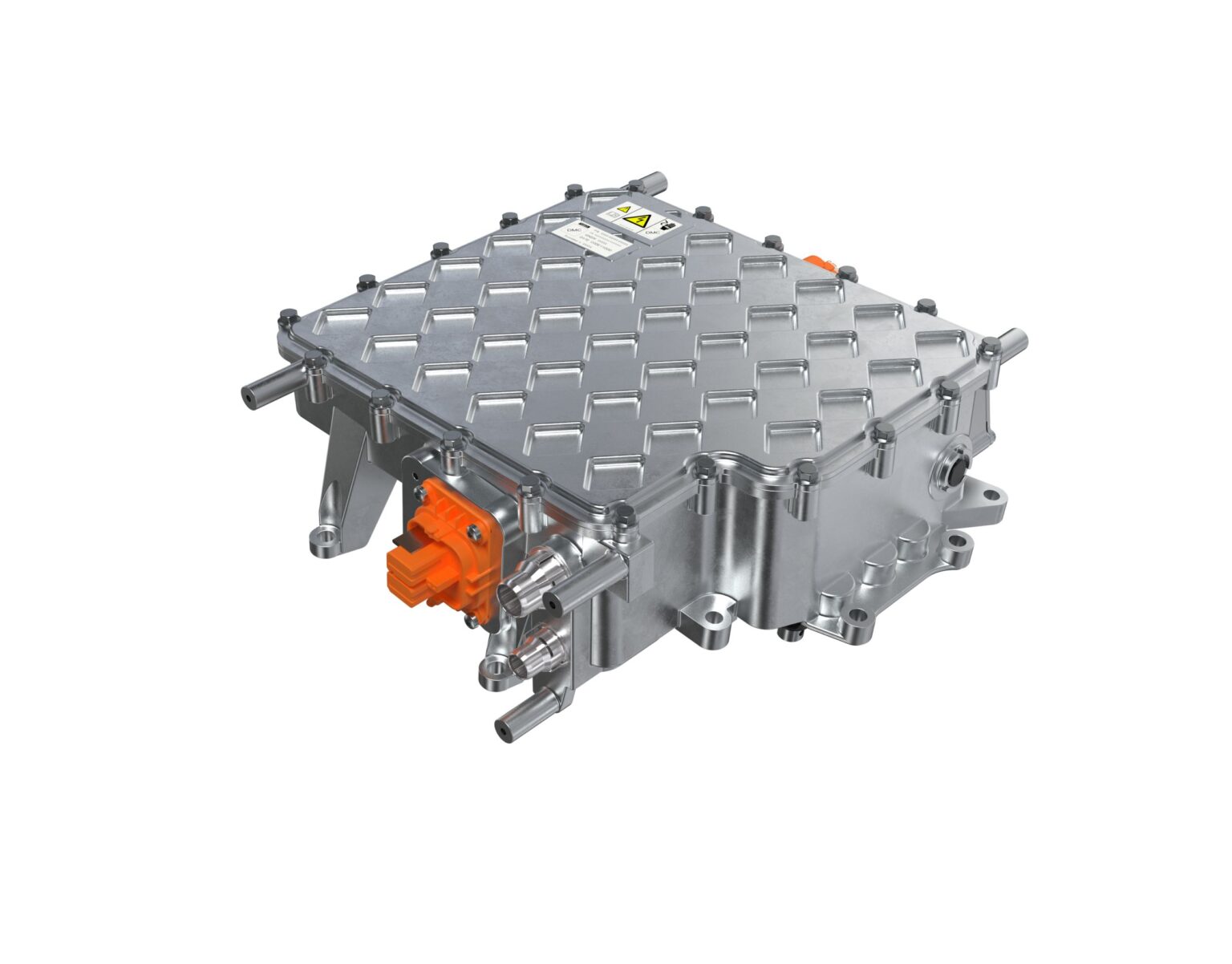

Schaeffler has taken a significant step in the field of vehicle electrification by receiving a major order for a dual inverter for the North American market. This device, which combines advanced technologies, is specifically designed for a new plug-in hybrid platform for pickup trucks, a highly popular segment in the United States.

The inverter not only controls the electric motor for auxiliary systems, but also acts as the main inverter, capable of powering the traction electric motor and delivering over 200 kW of power. This advancement not only strengthens Schaeffler’s position in a key market, but also establishes a partnership with one of the leading original equipment manufacturers in hybrid vehicle development.

Production of the dual inverter will take place at Schaeffler’s plant in Deer Park, Illinois, and is scheduled to begin in late 2027. Thomas Stierle, CEO of E-Mobility at Schaeffler, highlighted the speed with which the Deer Park team was able to develop this dual inverter, meeting the client’s rigorous requirements.

Meanwhile, Hassane El-Khoury, CEO of onsemi, emphasized the importance of EliteSiC technology, which integrates their experience in silicon carbide into the inverter platform. This technology promises greater electric range and improved vehicle performance, setting a new standard for plug-in hybrid trucks.

The development of the dual inverter has also presented significant challenges, especially in terms of the manufacturer’s strict specifications regarding installation space and efficiency. The requirements for the two inverter units are different: the starter-generator motor will use insulated gate bipolar transistors, while the traction inverter will be equipped with high-efficiency silicon carbide MOSFETs. This technological combination ensures optimal performance and minimal electrical consumption, thereby contributing to greater range in real-world conditions.

Source: MiMub in Spanish