Technological advancements in the construction machinery field have taken a significant step towards energy sustainability with the implementation of reduced friction roller bearings. These components, used in drive systems and hydraulic pumps, are designed to minimize friction by optimizing contact at the edges and surface structures, as well as improving the interior geometry of the bearings.

Although bearings generally exhibit low friction, cylindrical and tapered roller models tend to have extensive sliding parts that increase their friction torque. However, engineers at Schaeffler have achieved specific optimizations that have significantly reduced this ratio.

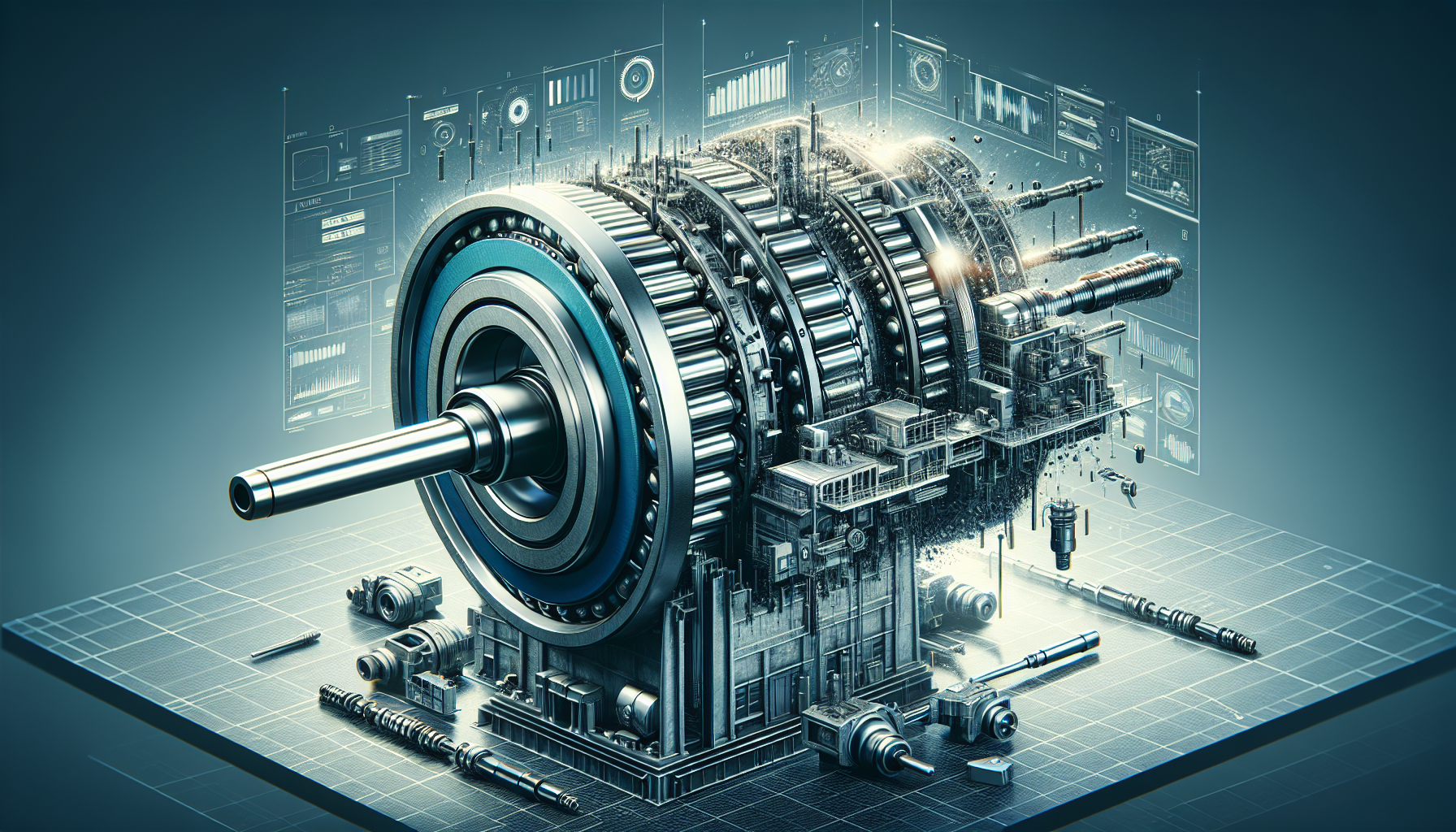

Cylindrical roller bearings, used in various applications within construction machinery, are especially effective in planetary gearboxes, where they offer significant advantages in situations with limited space and high radial load. Their ability to decrease friction directly impacts energy consumption, which is crucial in the fight against pollutant emissions.

A recent case study highlights the use of bearings in the hydraulic system of a 140 kW wheel loader. Thanks to the implementation of X-life quality bearings, an energy saving of up to 9 kW was achieved in a single machine. For a fleet of 1,000 loaders with standard operating times, this could translate into a reduction of 16,000 metric tons of CO2 annually.

Meanwhile, tapered roller bearings, which already had reduced friction characteristics, have seen significant improvements. Those designed under X-life quality not only offer greater energy efficiency and load capacity but have also increased their dynamic load capacity by 25%, thus doubling their service life. Additionally, the friction torque is reduced by up to 75% compared to conventional models, which also results in a considerable reduction of noise.

These innovations highlight the industry’s commitment to sustainability and energy efficiency, marking a trend that could change the landscape of construction machinery in the near future.