The DELTEC Group has taken a significant step towards modernizing its production plant in Furth im Wald, Germany, thanks to a strategic alliance with Panasonic, along with its partners Inovaxe and B4Creation. This collaboration aims to digitalize their surface mount technology (SMT) production process, promising a notable transformation in material logistics and traceability throughout the manufacturing process.

The company faced various challenges in material management and tracking, such as storage disorganization and manual data collection. To optimize their operations and provide real-time visibility, DELTEC Group sought to improve overall team efficiency and reduce search times, critical factors to avoid unplanned downtime and lengthy line changes.

To address these issues, an integrated production and material management system has been implemented, operating under Just in Time (JIT) and Just in Sequence (JIS) principles. This system is powered by Panasonic’s PanaCIM manufacturing execution software and integrates with Inovaxe’s smart storage solutions and B4Creation’s traceability platform. The integration covers aspects ranging from warehouse logistics to SMT production, manual assembly, and final product configuration.

Among the introduced innovations, a pick-by-light guidance system stands out, streamlining kitting processes, as well as intelligent reel verification to eliminate loading errors. Additionally, real-time inventory monitoring and a Kardex Pater Noster vertical storage system are available to maximize efficiency on the production floor. Materials are tracked from receipt to machines using PanaCIM’s Reel ID system, enabling predictive planning and automatic replenishment with full visibility.

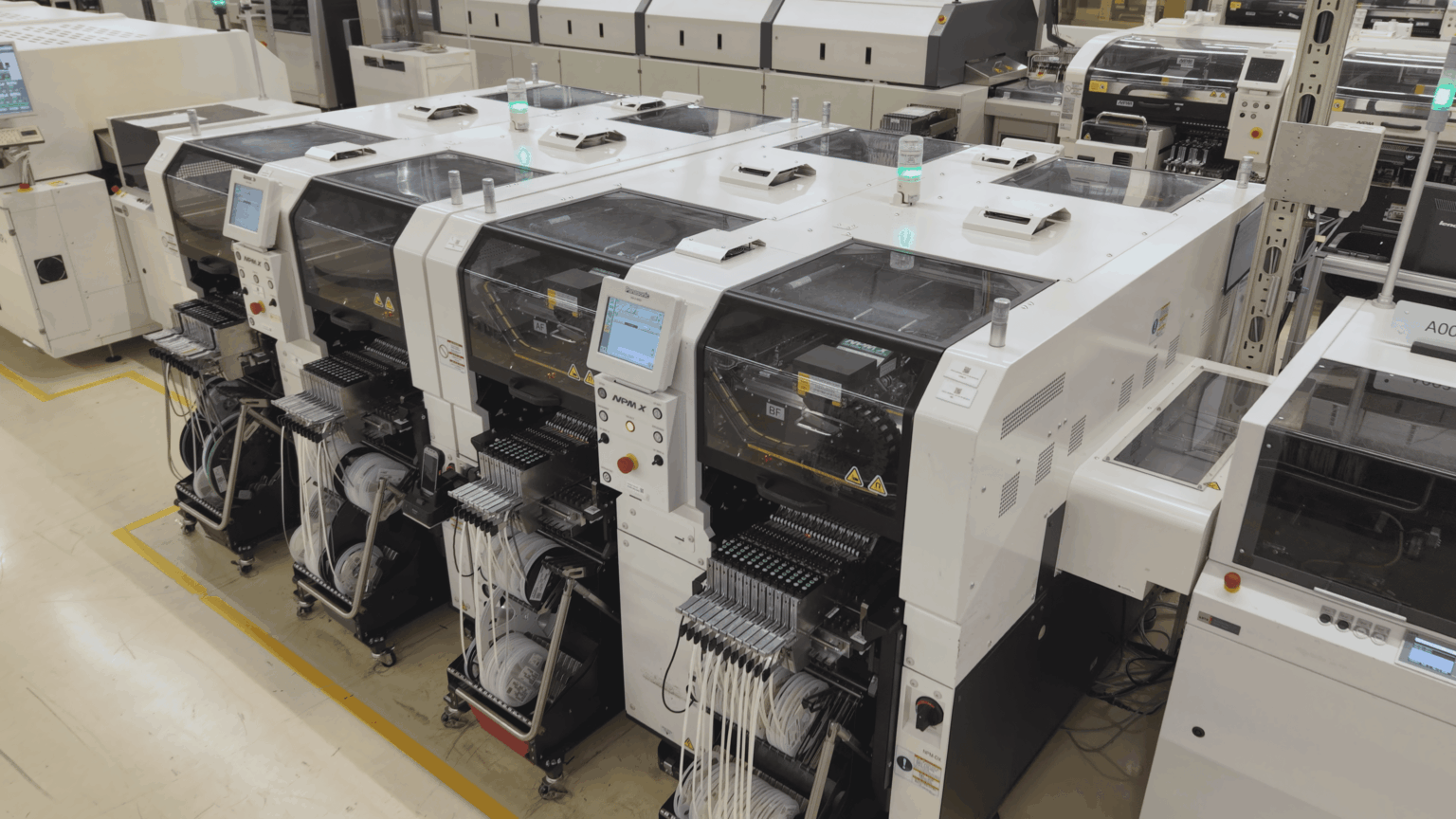

DELTEC’s new SMT line incorporates advanced equipment such as Panasonic’s SPG2 solder paste printer and modular placement machines NPM-W2, NPM-WX, and NPM-DX. With this equipment, along with automated production monitoring software, all information can be managed digitally in the PanaCIM system.

The consortium has also introduced an advanced THT line with integrated traceability, utilizing the Traceability By Design (TBD) software. This tool automates product configuration and defect detection, generating real-time key performance indicators (KPIs) such as First Pass Yield (FPY) and Overall Equipment Efficiency (OEE).

Thomas Fischer, Technology and Maintenance Director at DELTEC Group, stated that the implementation of PanaCIM has radically transformed the company’s operations. “The solution has allowed us to track materials accurately and organize them efficiently, significantly reducing search and collection times,” Fischer remarked. He emphasized that the automated generation of KPIs provides total transparency on production performance, helping to identify areas for continuous improvement in quality and efficiency.

via: MiMub in Spanish