Here’s the translation into American English:

—

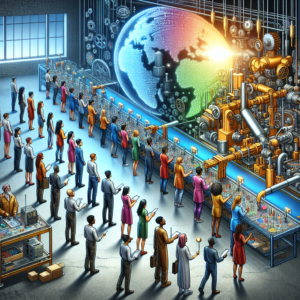

In recent years, reshoring has become a significant trend among manufacturers in the European Union and the United States. This movement, which involves bringing production processes closer to local markets, arises in response to various concerns related to the supply chain and an increasingly uncertain international environment. The trade tensions between the United States and China, which began in 2018, have intensified this situation, further exacerbated by the pandemic and rising geopolitical tensions in Europe.

A recent study reveals that 72% of companies are considering reshoring or nearshoring their production in the next 12 to 18 months. In the European Union, there have been 208 recorded cases of reshoring or nearshoring, with countries like the United Kingdom, France, Italy, and Denmark standing out for their activity in this area. However, in Spain, the phenomenon seems to still be in its early stages, with only nine identified cases, representing 4.8% of the total in the region.

Industry leaders identify several factors driving this decision. On one hand, domestic production allows for better control over the supply chain, particularly following recent disruptions. An impressive 89% of executives believe these disruptions pose the greatest risk to their companies.

Another relevant factor has been the increase in production costs in traditionally low-cost markets like China, where wages have risen by as much as 25% in recent years. Consequently, many manufacturers are evaluating the possibility of relocating their production lines to places with more competitive costs, such as Mexico or Eastern European countries.

Additionally, localizing production can speed up time to market, optimize logistics, and facilitate communication within the supply chain. Geographical proximity not only reduces time zone differences but also allows for more agile decision-making.

Production management also benefits, as growing demands for sustainability have led to increased interest in quality and durable products. Reshoring can improve access to skilled labor and facilitate compliance with legal and environmental regulations.

Finally, advances in automation technologies have made reshoring more viable and competitive. According to a study, robotic automation has reduced labor costs by more than 20% compared to manual processes. Accessible tools, like OnRobot’s D:PLOY, are enabling even small and medium-sized enterprises to benefit from these innovations.

In this way, the reshoring of production is solidifying as a crucial strategy for many companies seeking to adapt to an increasingly dynamic and complex environment.

via: MiMub in Spanish